AkeBoose chamber doctor blade systems are designed to make printers’ everyday life easier by offering smoothly functioning and cost efficient ink metering of superior and consistent quality.

Our range of chamber doctor blade systems covers the whole spectrum of flexo printing applications, from narrow web label printing to wide web flexible packaging as well as corrugated and tissue printing. To accommodate the specific needs of the individual printing application, our chambers can be equipped with special features for optimal function.

Core benefits of all AkeBoose chamber doctor blade systems

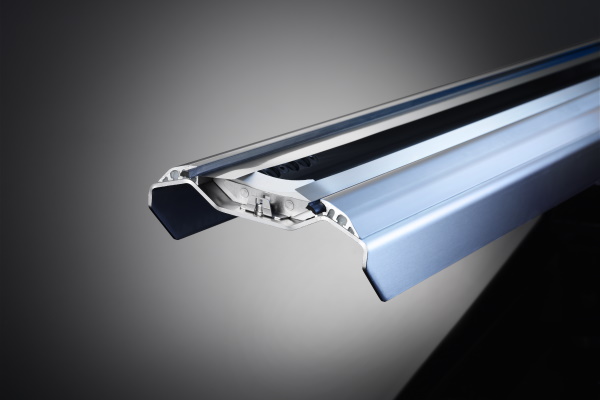

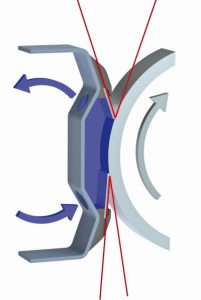

Thanks to the asymmetric chamber design, the angles at the doctoring blade and the sealing blade towards the anilox roller are optimized. This allows for a high precision and consistent ink wipe at the working blade, eliminating issues like ink spitting or ghosting.

At the same time, the enhanced flexibility at sealing blade lets ink from unemptied cells pass through back into the chamber, avoiding dripping at the sealing blade ("back doctoring") that tends to occur in symmetric chamber systems.

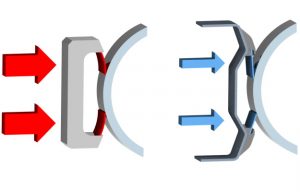

The “kiss impression” technology of our chambers is based on low-pressure doctoring. This means the chamber is running at minimum pressure against the screen roller. As a result, doctor blades and end seals wear much slower, reducing costly machine down time due to blade and seal changes considerably.

Thanks to the mechanically locked chamber positioning system, the chamber cannot be engaged with too much pressure against the anilox roller (overpressure is a common cause for scoring lines on the roller), which is beneficial for the anilox roller service life.

The patented blade clamping system makes it possible to change doctor blades in seconds, no need for tools or compressed air. The blade is securely clamped with a special rubber profile along the chamber.

Most AkeBoose chamber systems also feature a service position, so that doctor blades and end seals can be changed directly on-press, without the need for taking the chamber to a maintenance or service area.

The clean interior design of the chambers and easily accessible blade clamping system are very easy to keep clean. There are no corners or grooves where ink could deposit.

Consequently, printers can concentrate on printing rather than spending their time cleaning.

The ultimate payoff of all these core benefits are low operating costs for the chamber system while fostering excellent print quality.

![]()

OUR CHAMBER DOCTOR BLADE SYSTEM SERIES

![]()

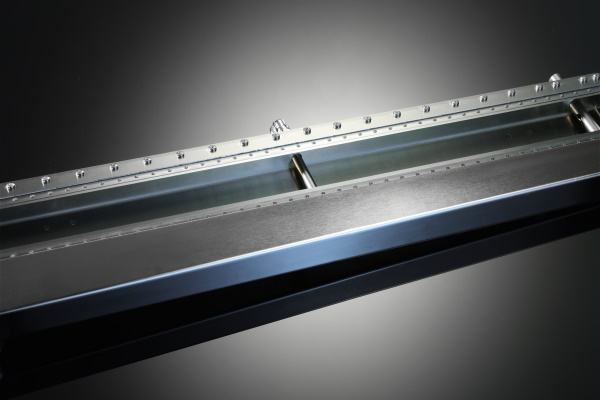

NOVA XLS

Powerful and sturdy stainless steel chamber system for medium to wide web flexo printing

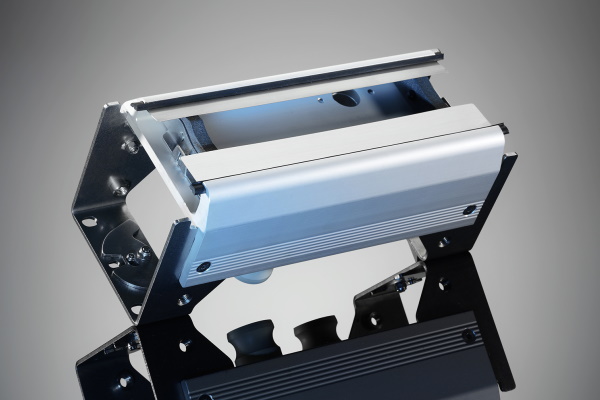

NOVA TK

Modular all-in-one chamber doctor blade system for straightforward flexo printing efficiency up to 6000 mm width.

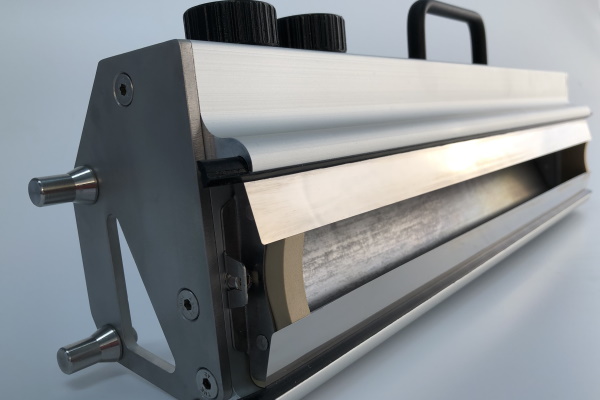

NOVA Compact

Slim one-piece chamber system for narrow to medium web flexo printing

NOVA RS

Chamber doctor blade system with ink reservoir for resource-efficient label printing

CLASSIC

Sturdy dual chamber doctor blade systems for leak-proof flexo printing