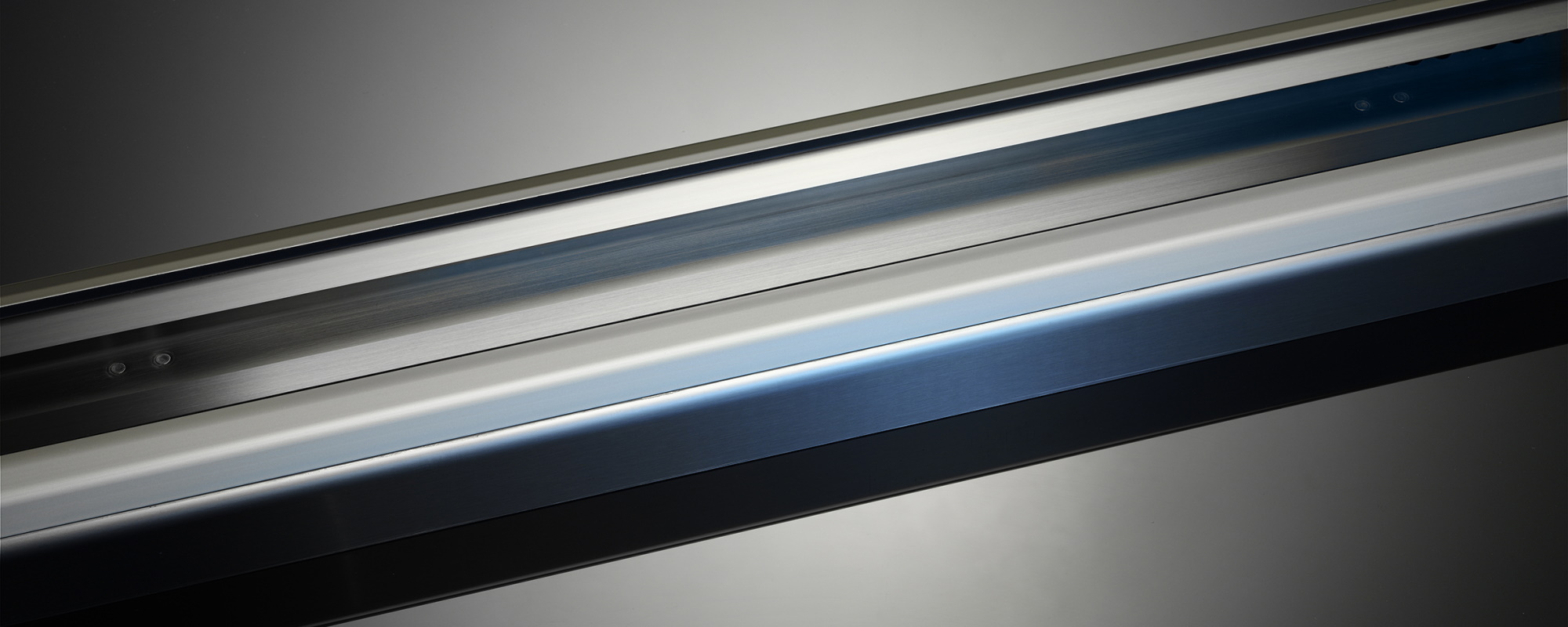

Highlights of the NOVA XLS chamber doctor blade system

Intelligent chamber design for an efficient and worry-free operation

Excellent mechanical and chemical resistance thanks to stainless steel chamber body

Very easy to keep clean and straightforward to service

Intelligent chamber design for efficient printing

Our "flagship" Nova XLS is a very versatile stainless steel chamber doctor blade system that plays its strengths in many flexo printing applications.

The slender chamber design is optimized for a consistent ink flow, resulting in excellent inking results. The asymmetric profile in combination with the low-pressure inking principle offers even and consistent doctoring results without ink spitting or back doctoring. Efficient venting mechanisms reduce the mixing of air and ink even at high printing speeds.

Robust and clean chamber set-up with minimum maintenance requirements

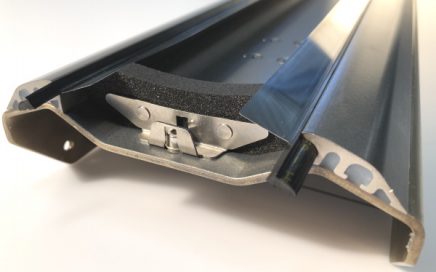

The stainless steel chamber body is very robust and resistant to mechanical wear and chemical impacts. The surface is corrosion-proof even when in contact with harsh inks and detergents, and is not damaged by cleaning with metal tools. At the same time, it is very easy to keep clean: The flowing chamber contours ensure that virtually no residual ink remains in the chamber after emptying, there are no edges or corners where ink can deposit. The blade clamping features a rubber profile along the entire chamber, which seals the blade slot against ink.

The mechanical stop of the NOVA XLS suspension system makes the system run very stable and keeps the blades straight as they are meant to be, avoiding the risk of excessive pressure towards the anilox roller. To compensate blade wear during printing, the chamber position can be finely adjusted.

Quick and straightforward on-press change of end seals and doctor blades

The integrated service position and patented blade clamping method allows quick and effortless on-press changes of end seals and doctor blades without the need for any special tools. Accordingly, it is also possible to clean the chamber manually on-press. The chamber can also be easily disconnected from the suspension system for comprehensive cleaning and ink changes. Although made of stainless steel, the chamber weighs less than 8 kg per meter and can therefore be handled ergonomically.

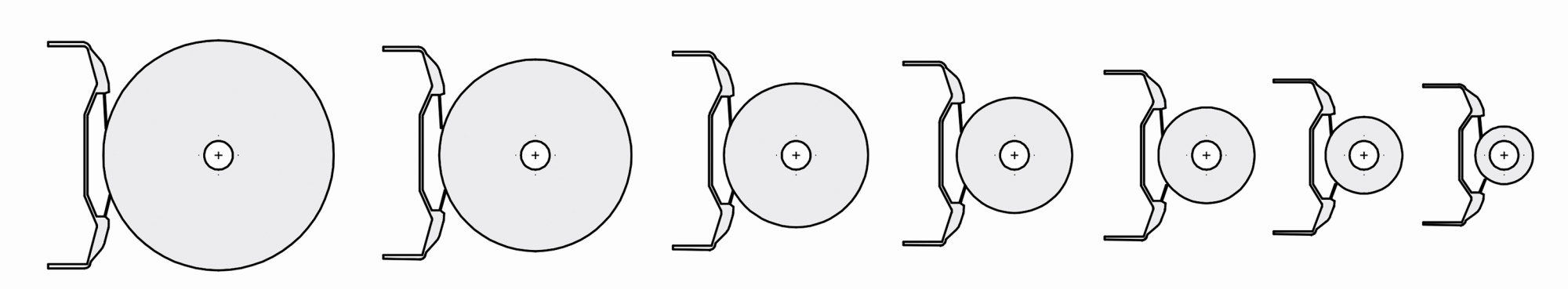

Optimal doctor blade angles guaranteed

The NOVA XLS chamber doctor blade system covers printing widths of up to 4 meters (157 inches). For an optimal doctor blade angle, it comes in 7 profile sizes to fit anilox diameters up 675 mm (26 inches).

Options for NOVA XLS

Water-borne inks for printing on film are designed to cure quickly on non-absorbent substrates like film. The downside is that they also dry up quickly on the end seals of the chamber, where the frictional heat causes evaporation. Semi-dried lumps of ink then quickly destroy the seal and printers using water-borne inks are often struggling with leaking end seals.

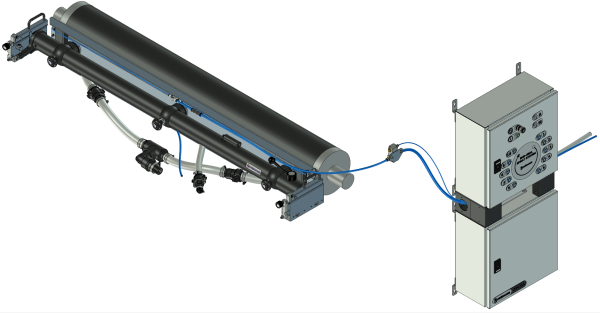

The AkeBoose end seal spray system (“ESS”) for NOVA XLS humidifies the end seal area constantly during printing to make sure that the end seals stay clean and highly functional.

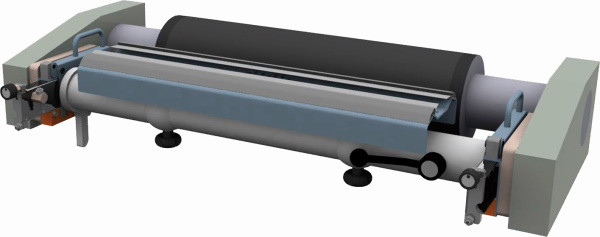

Closed loop outlet for balanced ink handling

NOVA XLS is available with a closed loop ink circulation, i.e. both inlet and outlet are directly connected to the ink hoses. The outlet is self-venting to ensure an unobstructed ink return flow either by return pump or by gravity return. The closed loop outlet is required for printing presses with automatic washing systems, so that the entire ink cycle can be cleaned.

Open outlet with ink collection for extra leak-protection

To guarantee 100% leak-proof printing, the NOVA XLS outlet can be equipped with an open ink return which leads leaking ink from the end seal area back to the return hose. This allows to finish the print job even if the seal should not work perfectly until the job is done. The open ink return covers the outside ends of the chamber. For smaller chambers, the open ink return covers the entire length of the chamber.

In some printing applications, the mechanical stress on the chamber system is more pronounced – for example when very high printing plate thicknesses are used like in corrugated sheet post-printing. To make the chamber stay firmly in position for printing and to avoid bouncing, the NOVA XLS comes with a special and extra-rigid suspension system.

The chamber body of NOVA XLS is made of stainless steel by default. When highly corrosive ink types and cleaning chemicals are involved, all wet chamber parts including the blade clamping profiles can be made of stainless steel as well.

The inside of the chamber, where in contact with ink, can be coated with a non-stick PTFE layer. That makes it more difficult for ink particles to deposit in the chamber, which makes cleaning of the chamber even easier and faster.

Some applications have the anilox roller rotate in two directions. In this case, the chamber needs to be symmetric so that both blades can work either as working or containment blade.

Since symmetric chambers can never be made to be truly leak-free, we always recommend combining symmetric chambers with an open outlet with ink collection.

Application area of NOVA XLS:

- Medium to wide web flexo printing

- Flexible packaging

- Corrugated

- Coating applications

- Tissue printing

- Harsh printing conditions

- All types of printing inks (solvent, water, UV) and coating compounds

![]()

RELATED TOPICS

![]()

End-seal Spray System for printing with quick-drying water-borne inks on plastic film

No more clogged end seal areas and leakage thanks to the special end seal humidification system! Read more

EPQ 200 compact ink supply system for consistent print quality

Easy to handle and clean ink management for a low-pulsation and balanced ink flow. Read more