What is corrugated?

Corrugated board is a special type of cardboard, consisting of three layers of paper sheets that are glued together. The paper layer in the middle is made into a wave shape, the so-called flute. The outer two outer paper layers are glued to the mounds of the corrugations of the middle layer. This material structure makes the board stable and strong without giving it too much dead weight. There are different types of flute shapes, which are particularly suitable for specific purposes of the final corrugated board product.

The range of corrugated products can vary from simple-looking boxes with mere protection purpose to a marketing tool on the shop floor, like for example high-quality print promotional displays that are designed to catch attention.

Examples of corrugated products

Sales packaging

Product packaging, e.g. for electronics or household appliances

Transport packaging

Protective packaging for the safe transport of goods

Displays

POS (Point Of Sale) and promotional displays

Characteristics of corrugated printing

Printing of corrugated materials can happen in two ways: Either the top paper layer (“liner”) is printed before it is glued to the corrugated middle layer – this is called preprint – or the corrugated board is printed after all three paper layers have been glued together. The latter procedure is called post print.

Corrugated preprint is a roll-to-roll printing procedure (mostly on CI-flexo presses) and is strictly speaking a subtype of flexible packaging printing. The advantage of preprint is that a thinner (and thus less costly) liner can be used and that superior print quality can be achieved.

In corrugated post print, the printing is done on sheets. Post print is divided into two subcategories: Direct post print and inline post print. In direct post print, the corrugated board is printed on a designated flexo post printer, which can achieve high print quality for small to medium-sized print runs. Inline post print means that the printing and converting like die-cutting or folding and gluing is done on one and the same machine. Inline post print allows the economic production of small print jobs with simple print images, which is typically used for transport and protective packaging.

If we look at the corrugated post print process, this can be characterized in general as follows:

Most modern flexo post printers have a capacity of around 10,000 sheets per hour, that corresponds to a printing speed of about 250 m/min for print lengths of 1500 mm. This is due to the fact that the transfer of sheets between printing units is more complex than in roll-to-roll printing in pre-print or other flexible packaging applications.

The typical job size can be finished in one to two shifts.

Corrugated paper is an absorbent substrate, which is predestined for use in combination with water based inks.

The print surface on corrugated board is not 100% even, due to the liner being glued to a wavy structure. In order to make sure that the printing plate touches all necessary parts of the substrate, very thick printing plates are used with rather high employing pressure. This creates vibrations in the system that printers need to master, which is especially crucial when the aim is to print high quality graphics.

Depending on the type of product that needs to be printed, the quality requirements for the print image differ.

How AkeBoose can support you in the corrugated printing process

AkeBoose offers robust and corrosion-safe chamber doctor blade systems and ink supply systems that are designed to master the varying quality requirements and sometimes harsh printing environment of corrugated board production up to 4 m printing width.

Our product solutions are built for minimum maintenance requirements and are easy to clean, with the intention to support you in increasing the efficiency of your printing operation.

![]()

OUR PRODUCT SOLUTIONS FOR CORRUGATED PRINTING

![]()

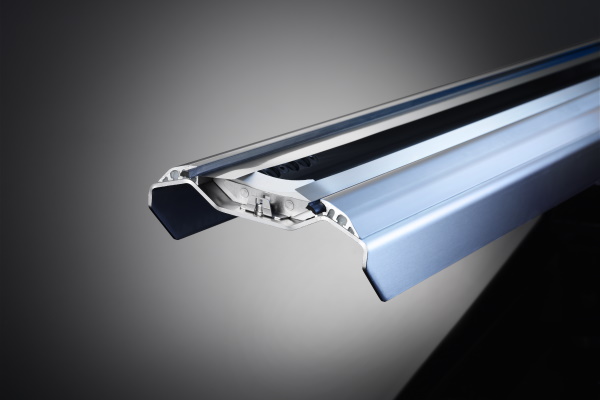

NOVA XLS chamber doctor blade system

Corrosion-safe and surface-resistant stainless steel chamber doctor blade system for consistent printing results and easy cleaning.

NOVA TK chamber doctor blade system

Strong and easy to keep clean chamber system that can be used both with plastic and steel doctor blades. Supports your corrugated printing perfection by avoiding bouncing.

EPQ 200 ink supply system

Compact and easy to handle ink supply system for a balanced ink flow.

EPQ 300 ink supply system

Compact and especially easy to clean two-container ink supply system.