What is a decor?

The idea of a decor is to give a product an appealing look. While this is admittedly the generic idea of any printed product, printed decors cover a special range of products, being mainly surface decors, metal packaging and bottle caps, also referred to as white caps.

Examples of decor products

Surface decors

Floor coverings

Furniture films

Wallpapers

Metal packaging

Beverage cans

Spray cans

Storage tins / canned goods

Decorative tins

Bottle caps

Crown caps

Screw caps

Characteristics of decor printing

The types of products united under the name of decor are very different, and so are the printing processes. The printing methods used in decor printing are primarily flexo printing and rotogravure printing, but there are some applications printed in offset, especially in metal packaging. While flexo tends to be favored for smaller print run lengths and flexibility in material choice, gravure printing is used for decor types with very high print quality requirements and/or long print run lengths.

If we look at metal packaging printing compared to surface decor printing, the typical aspects of the printing process differ quite considerably.

Typical metal decor printing characteristics

Sheets are usually converted to the final metal package straight following the printing process. In some cases, the printing is even done on the ready-shaped metal product (e.g. with soda cans).

The thin metal sheets need to be handled carefully which limits the press speed.

These have the most suitable adhesive properties for a metal substrate.

The print image on a spray can does not necessarily need to have the same print quality as a decorative gift box.

Typical surface decor printing characteristics

Surface decors are thin layers that are attached to objects like furniture, doors or floors and thus need to be flexible to perfectly merge with the surface.

While the continuous web printing process generally support high printing speeds, the quality is more important than the speed.

Since surface decors need to have pronounced resistance to scratches, wear and fading, but also against cleaning liquids, the ink formulas often include additives that are not found in standard printing inks.

Surface decors are often used for home interior products and therefore need to be of impeccable print quality.

How AkeBoose can support you in the decor printing process

AkeBoose equips you with high-precision and flexible metering systems and ink supply systems that support you in meeting the high quality requirements of decor products. The easy handling and low-maintenance design of our product solutions enable you to efficiently focus on your core activity printing and finishing.

![]()

OUR PRODUCT SOLUTIONS FOR DECOR PRINTING

![]()

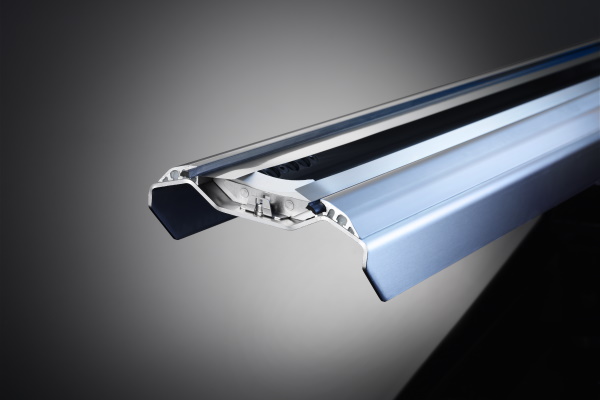

NOVA XLS chamber doctor blade system

Consistent and high-quality ink metering in flexo printing with excellent mechanical and chemical resistance

EPQ 200 ink supply system

Compact and easy to handle ink supply system for a balanced ink flow

EPQ 300 ink supply system

Compact and especially easy to clean two-container ink supply system.

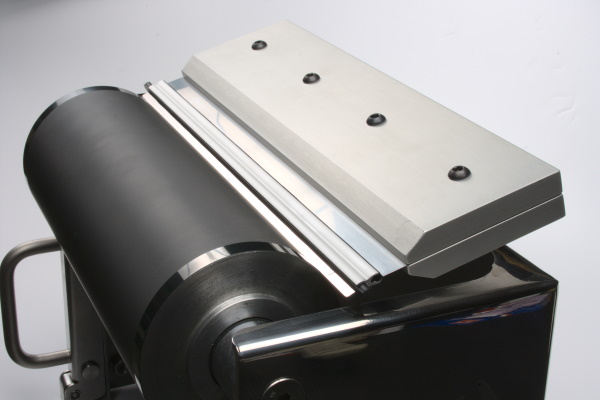

Blade holders for rotogravure printing

Doctoring system replacing the traditional lamella doctor blade for excellent doctoring precision and considerably reduced blade costs

Special solutions for ink temperature control

Special machinery and components tailored to your individual application