Highlights of the EPQ 300 ink handling system

Low-pulsation ink supply for a smooth ink flow

Integrated cleaning function for ink tubes and chamber system

Easy to handle

Offers low operational costs

Optimal ink flow thanks to dedicated ink supply and return pumps

The EPQ 300 ink pump system is designed for a low-pulsation ink flow between ink containers and chamber doctor blade system, fostering consistenly high print results in flexographic printing.

Like the EPQ 200 ink supply system, the EPQ 300 features two ink pumps: A dedicated ink supply pump with pulsation dampener and integrated volume flow control, which assures a steady ink flow to the chamber. A dedicated ink return pump feeds the ink from the chamber back into the ink container. The return pump speed and flow rate always follows the supply pump to avoid that overpressure or vacuum in the chamber.

Easy cleaning thanks to two-container setup

For easy cleaning of the chamber and ink tubes, two containers can be connected to the EPQ 300 system - one with ink and one with cleaning liquid. When an ink change needs to be performed, the process is as simple as follows:

- Stop the ink circulation

- Evacuate the ink from the chamber. The EPQ 300 features a reverse flow function for the ink supply pump. This means that both supply pump and return pump can be set to pump ink from the chamber back to the ink container, so that the chamber is emptied much faster.

- Clean the ink cycle and chamber system. This is simply done by flipping one single lever - then the supply pump switches from ink to cleaner, which is then flushed through the cycle (and also pumped back into the container with cleaner), reducing manual cleaning necessities to an absolute minimum.

- During the cleaning process, a container with new ink can be placed, so that the system is ready to start production with the new color immediately when the cleaning is done.

All these aspects save time and manual work in the cleaning process so that the press can be more productive.

Suitable for water-borne and solvent based inks

The EPQ 300 ink supply system works with all typical flexo solvents and water-borne ink types. When used with solvent based inks, the system will be built and certified accoring to ATEX regulation.

Water-borne inks

Solvent based inks

Easy operation thanks to straightforward design

Thanks to the compact enclosure of the EPQ 300 ink handling system with all pump parts inside, it is easy to integrate the system with the press.

For installation, there are two options: Either the pump enclosure is wall-mounted at the press, alternatively it can be delivered with a stainless steel frame so that it can be placed on the floor. The stainless steel frame is made in a way that allows to place the two containers comfortably directly under pump enclosure.

The operator panel is intuitive to handle with robust push-buttons and levers. The operator simply needs to choose between supply or evacuation mode and from which container to pump.

![]()

RELATED TOPICS

![]()

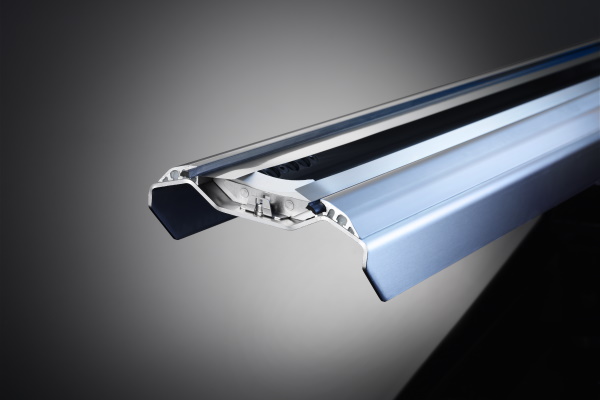

NOVA XLS stainless steel chamber system for medium to wide web printing

Clean design for high precision doctoring at low operating costs. Goodbye back doctoring, hello efficiency! Read more

How to choose the most suitable ink supply system

Find out about the various ink pump types and their suitability for different applications in this article. Read more