Highlights of the EPQ 200 ink handling system

Balanced ink supply for consistently high print results

Easy to operate

Facilitates the cleaning process of the chamber system

Offers very low start-up and running costs

Two-pump principle for optimal ink circulation

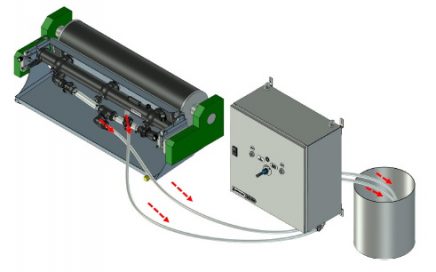

The EPQ 200 ink pump system helps flexographic printers to assure a consistent print quality. The system is specifically designed for flexo printing machines equipped with closed chamber doctor blades systems.

The EPQ 200 works on a two-pump-principle: The dedicated low-pulsation ink supply pump with integrated volume flow control makes sure that the ink flows steadily to the chamber. The dedicated ink return pump controls the amount of ink in the chamber to avoid overpressure, which would have a negative impact on the ink transfer from the chamber to the anilox roller.

Flow inverter for effortless cleaning

To facilitate cleaning of the chamber, the flow direction of the supply pump can be inverted, which means that the chamber is actively emptied by two pumps. This way, the ink evacuation is much faster and less ink residue remains in the chamber compared to gravity return.

Additionally, the EPQ 200 allows to flush cleaner through the cycle so that little manual cleaning will be necessary.

Suitable for all printing ink types

All typical flexo solvents and water-borne ink types can be handled with the EPQ 200 ink supply system. When used with solvent based inks, the pumps will be ATEX-certified and equipped with grounded parts.

Water-borne inks

Solvent based inks

Compact design for easy handling

The integration of the ink handling system with the press is extremely straightforward, since the EPQ 200 comes as a compact enclosure with all pump units inside.

The enclosure can either be wall-mounted at the press or placed on an optional stainless-steel frame, putting the operation interface at ergonomic work height. Depending on the amount of printing decks to be supplied, up to 4 pump units can be integrated in one enclosure to save floor space.

EPQ 200 setup for one to four printing stations

![]()

RELATED TOPICS

![]()

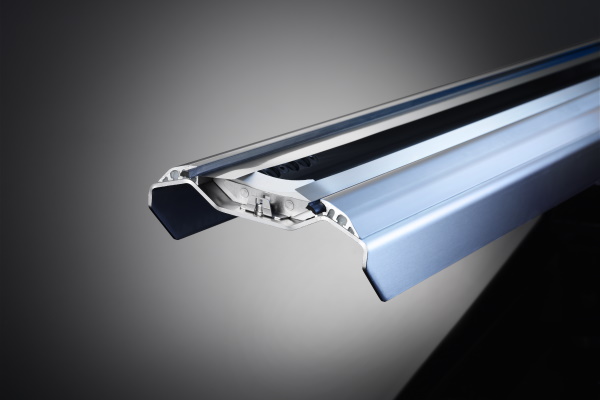

NOVA XLS stainless steel chamber system for medium to wide web printing

Clean design for high precision doctoring at low operating costs. Goodbye back doctoring, hello efficiency! Read more

End-seal Spray System for printing with quick-drying water-borne inks on plastic film

No more clogged end seal areas and leakage thanks to the special end seal humidification system! Read more