What are labels?

Labels are a piece of paper, plastic film, metal or fabric that is attached to a product or the product packaging /container. While the innate use of a label is to give information about the product, it has evolved to a marketing instrument as well, trying to catch the eye of the consumer versus competing products. We distinguish between self-adhesive labels, wet glue labels, in-mould labels and sleeve labels.

Self-adhesive labels have a sticky layer on the back and stick by themselves. The labels sit on a liner from which the label is peeled off for use. Wet glue labels are dry labels, i.e. glue needs to be applied to the label before it can be attached to the product. Sleeves are tubular labels with a 360° print on it.

Examples of labels

Self-adhesive labels

Labels for cosmetics, personal care and household goods

Labels for signage

Tapes

Wet glue labels

Labels for glass and bottles, mainly food and beverages

Stamps

In-mould labels

Labels fused into packaging of food, beverages, pharmaceutical, healthcare and other products

Sleeves

Stretch sleeves

Shrink sleeves

Characteristics of label printing

Labels are produced with different printing methods, being flexo, offset, screen or digital printing. Flexo printing is the most common method. Most label printing presses are so-called hybrid presses, which means that they combine different printing methods. E.g. for a white primer, usually a screen printing unit is used before the actual print motif is printed with flexo printing decks.

Flexo roll-to-roll printing of labels is typically characterized by

The average printing speed is around 80 to 100 m/min. The limiting factor is in most cases the converting process like the in-line removal of the waste matrix for self-adhesive labels.

Compared to lot sizes in flexible packaging, a much smaller volume per print job is produced in label printing. The setup of label presses allows the economic production of small batch sizes.

Labels are a very important means of product differentiation from the competition and have a high influence on the consumer’s buying decision process. An excellent print quality is therefore rather a must-have than a nice-to-have.

UV inks generate very bright colors and vivid images, dry quickly, are scratch-proof and are not subject to viscosity fluctuations and thus offer a consistent ink quality.

Modern printing presses often have a modular machine set up, so that they can combine different printing methods and optical and haptic design elements such as foil embossing or relief coating in one print run.

How AkeBoose can support you in the label printing process

AkeBoose is specialized in chamber doctor blade systems that are tailored to the high print quality requirements in label printing.

Our systems support you in mastering the challenges related to UV inks so that you can rely on smooth printing operations without back doctoring or ink spitting. They offer easy handling and cleaning and are cost-efficient and sustainable in operation and maintenance.

![]()

OUR PRODUCT SOLUTIONS FOR LABEL PRINTING

![]()

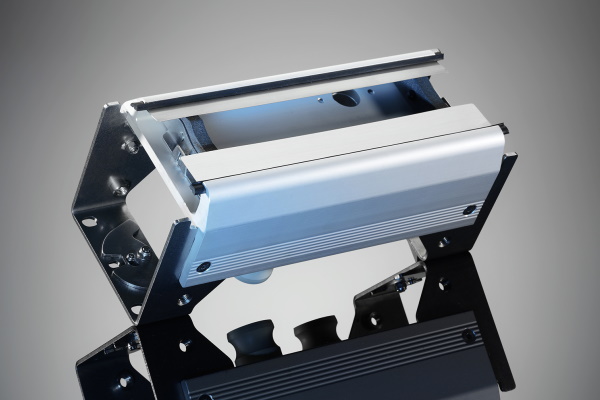

NOVA Compact chamber doctor blade system

Light-weight and flexible one-piece chamber system for high quality print results.

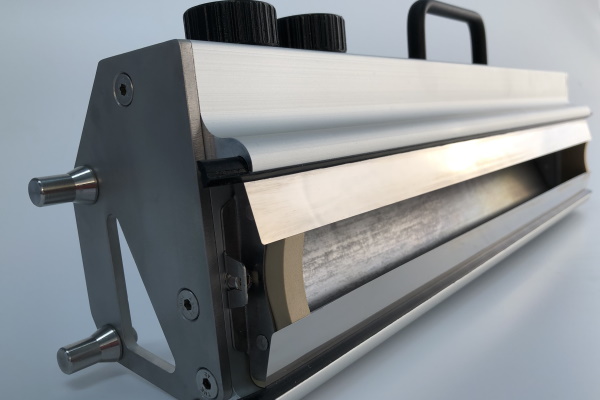

NOVA RS chamber doctor blade system

Chamber system with ink reservoir for clean and high precision printing of UV inks without the use of ink pumps.

NOVA TK chamber doctor blade system

All-in-one modular chamber system for easy integration and high-quality label printing.