Highlights of the NOVA TK chamber doctor blade system

Ink-saving, leak-proof flexo chamber technology

Low-wear precision doctoring for resource-efficient printing

All-in-one modular chamber for quick and easy handling

Designed to make your flexo printing life easier

Press uptime is key to profitable flexo printing. The NOVA TK chamber system is made for leak-proof and resource-efficient printing. Thanks to the modular set-up, NOVA TK can be customized to guarantee maximum efficiency in your flexo press.

With NOVA TK, you bring down machine downtime related to wear and leakage. This means you increase your productivity and reduce operational costs, so that the moderate investment for the NOVA TK system is quickly earned back.

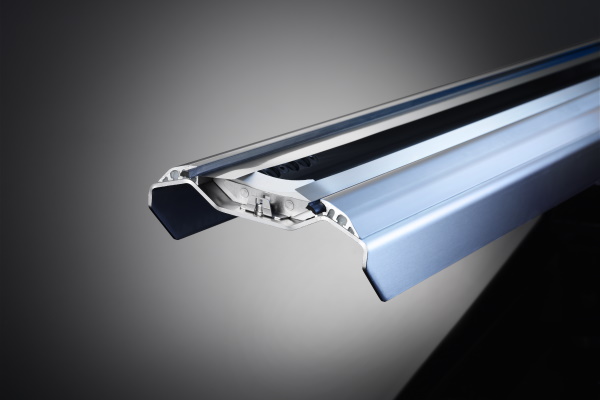

Clean one-piece technology

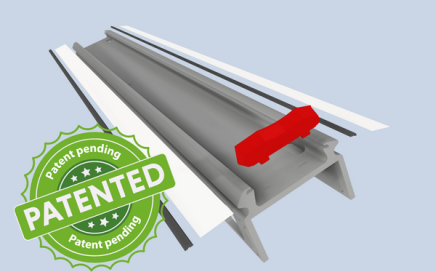

The asymmetric contours of the chamber body are shaped in a way that guarantees leak-proof operations and easy evacuation of the chamber to almost 100%, which saves valuable ink.

Accordingly, cleaning requirements are minimal, especially since the blade clamping is integrated into the chamber body without any mounting parts where ink could stick and dry.

Low-wear precision doctoring

The rigid shape of the profile guarantees doctoring precision at wide formats of up to 6000 mm. Up to a width of 1200 mm, the chamber is even self-supporting and does not require a support beam. The proven AkeBoose “kiss-impression” low-pressure doctoring principle ensures an optimal ink wipe with minimum wear of end seals and doctor blades.

The average flexographic printer changes blades twice per week. With AkeBoose kiss impression chamber technology, printers have been able to run several weeks to months with one set of doctor blades.

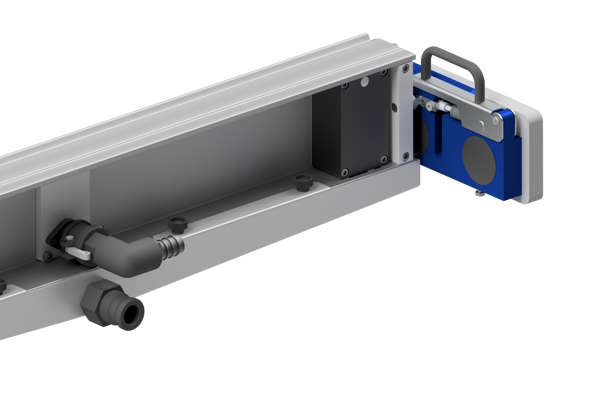

Quick and easy blade and seal changes

Changing doctor blades and end seals requires very little time without any tools or mechanical aids such as compressed air. The blade is simply fixed with a rubber profile in the blade slot, which not only makes the blade sit tight and straight, but also prevents the blade slot from ink contamination. The end seal is easily and safely locked in place in a designated slot in the chamber back. This fixation system is patented.

Modular system matching you printing application

Special NOVA TK features for flexible packaging printing

The asymmetric set-up of NOVA TK makes sure that the doctor blade wipes the ink precisely and continuously, even at high screen counts in HD-flexo printing and advanced printing speeds. At the same time, the containment blades seal along the chamber securely without the risk of back-doctoring.

The self-supporting version of the chamber can be completely removed for service work.

The special shape of the chamber is both rigid and very light, allowing one person to handle the chamber. This makes it easy to use extra chambers when changing inks.

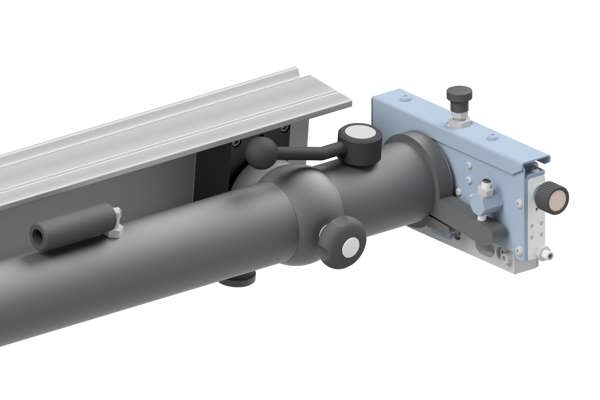

Special NOVA TK features for corrugated printing

The suspension compensates strong mechanical impacts from uneven substrates and thick printing plates, avoiding bouncing and print defects.

Both plastic and steel blades can be used, simply by using a different color-coded fixing rubber profile.

The one-piece technology prevents accumulation and drying of ink. This saves a lot of time and effort used for cleaning, especially for water-based inks.

![]()

RELATED TOPICS

![]()

NOVA XLS stainless steel chamber system for medium to wide web printing

Clean design for high precision doctoring at low operating costs, even at harsh printing environments! Read more

EPQ 200 compact ink supply system for consistent print quality

Easy to handle and clean ink management for a low-pulsation and balanced ink flow. Read more